News from Glynwood

Through the serene hush of winter, Glynwood’s Multiflora Rose Thicket Restoration Project has continued behind the scenes. The ground, frozen and unyielding, patiently awaits the warmth of spring to resume its transformation. In this final installment of our restoration series, we share the behind-the-scenes preparations that promise a vibrant rebirth come April 2024.

Today, we highlight our dedicated community crew of five passionate individuals who have embarked on a transformative restoration project that goes beyond simply removing bushes and building a dead hedge.

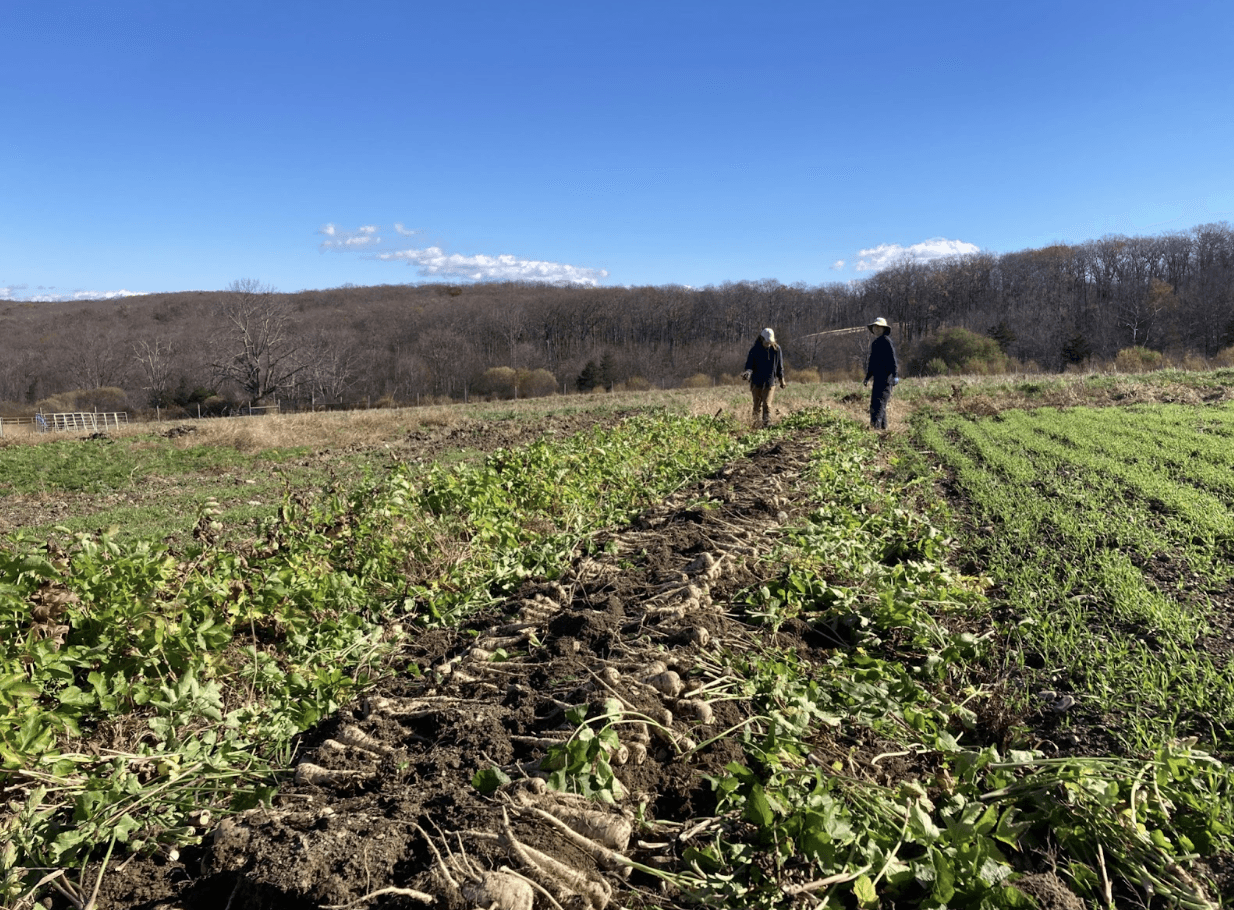

In the third installment in our series on the Multiflora Thicket Restoration project, we highlight the remarkable efforts of our dedicated volunteers. With sweat-drenched brows and a shared commitment to environmental stewardship, the Hudson Valley community and our dedicated Glynwood crew have worked tirelessly to remove invasive species and help restore a more optimal environment for native plants.

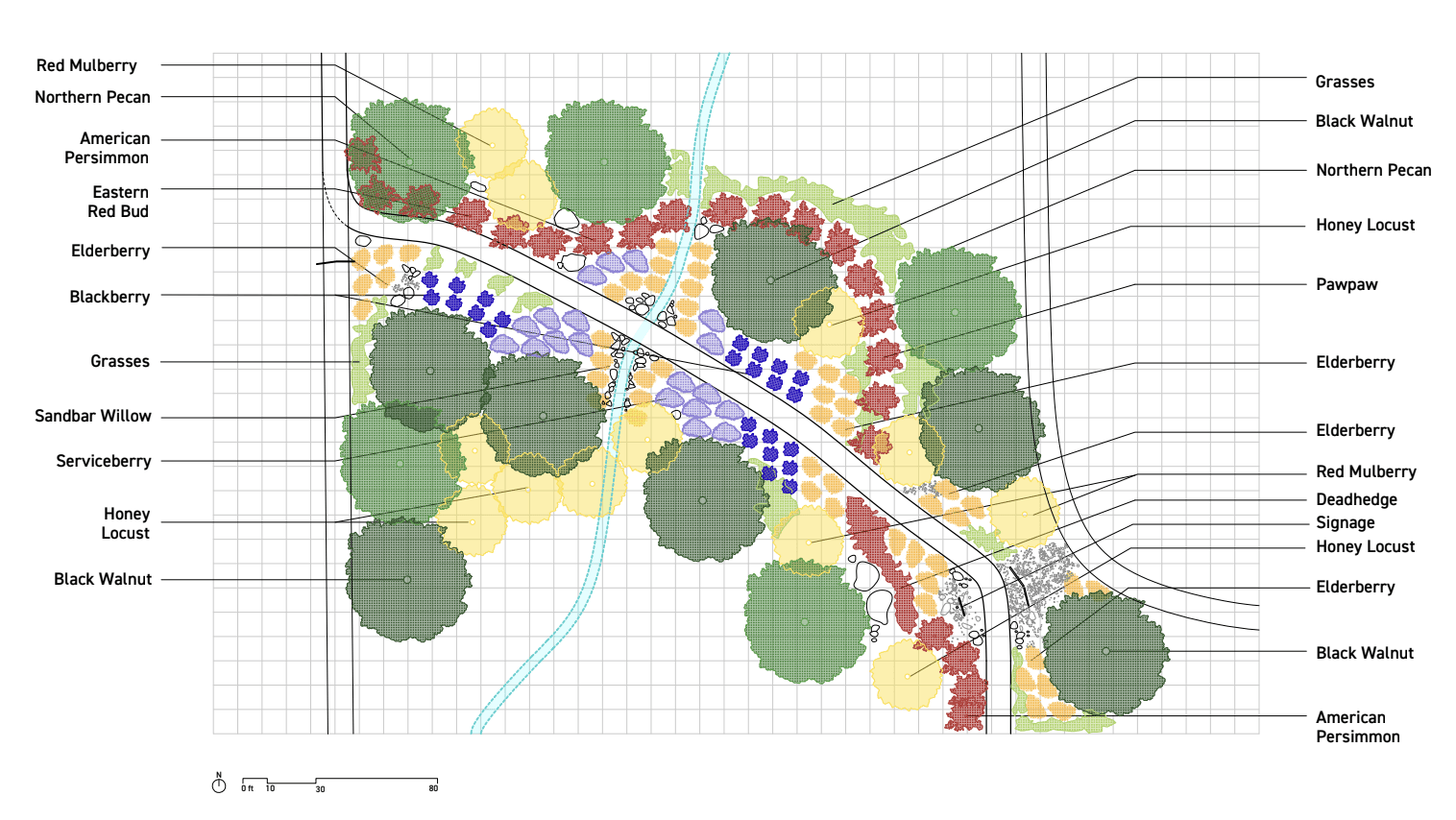

In this update, we highlight the progress of the Multiflora Thicket restoration project, integrating ecological restoration with agricultural conservation practices. Restoration Agriculture aims to revive the ecological well-being of working landscapes by blending native and naturalized plant species to mimic native ecosystems. This approach delivers climate resilience benefits to farm operations while maintaining advantages such as biodiversity enhancement, water quality improvement, carbon sequestration, and wildlife support.

Last October, Colette Rossant—author, cooking teacher, restaurateur and a longtime friend of Glynwood—died at age 91 after a long and full life. Colette had a singular influence on Glynwood’s Regional Food Programs inspiring us to support the regional identity and food culture of the Hudson Valley through cultural exchanges and building markets for local products.

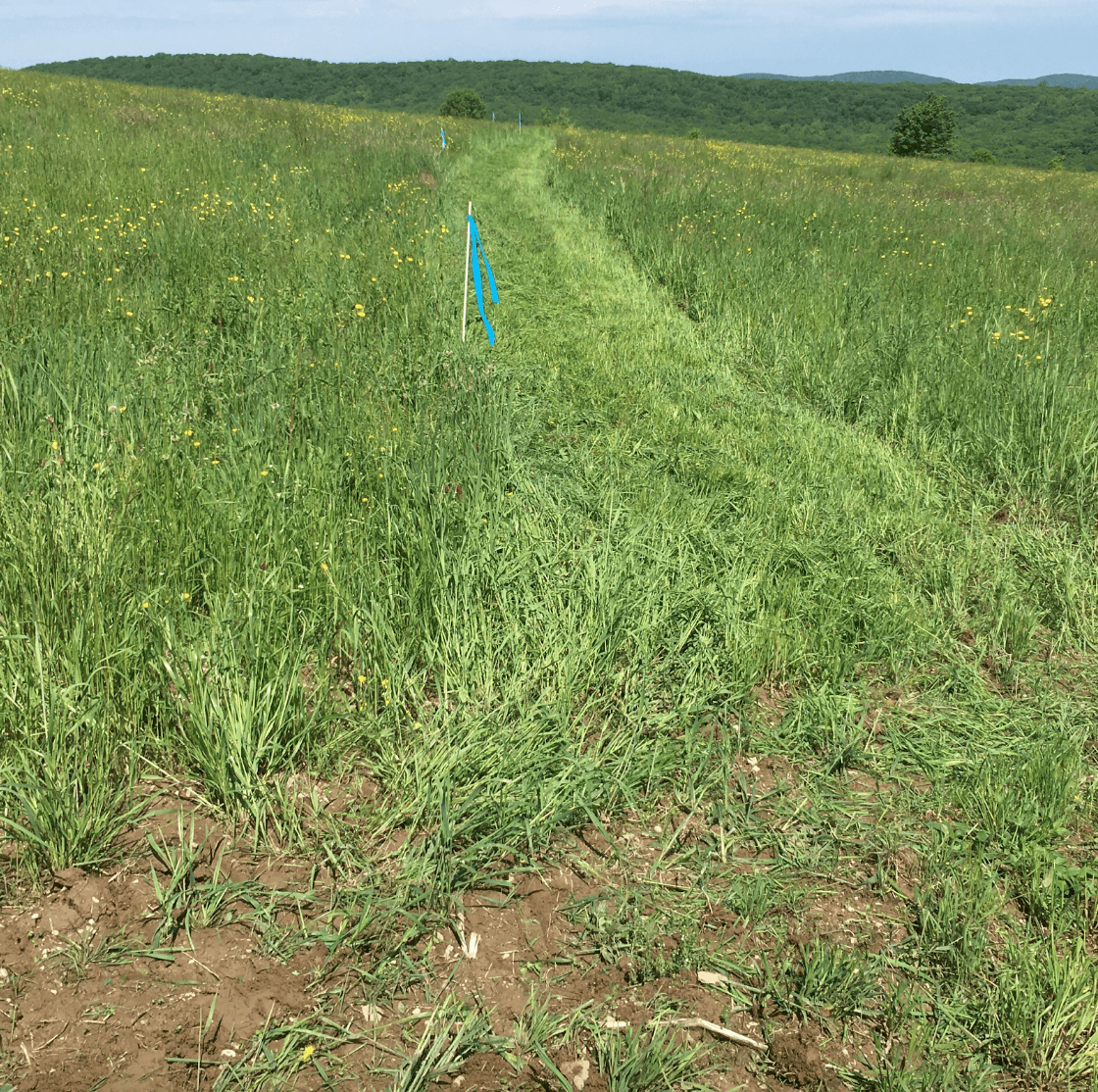

Last summer, alongside fellow Community Crew member Mari and Matthew, Glynwood’s Agriculture Project Manager, I marveled at the thriving roots of two-week-old Willow cutting plants. This was the first step in propagating native plants for Glynwood's Climate-Smart Restoration Project - a transformative initiative that embraces ecological restoration methods for Glywnood’s working lands. Guided by recommendations from a recent biological survey, Glynwood is committed to establishing a visible and accessible public demonstration of regenerative, climate-smart ecological restoration.

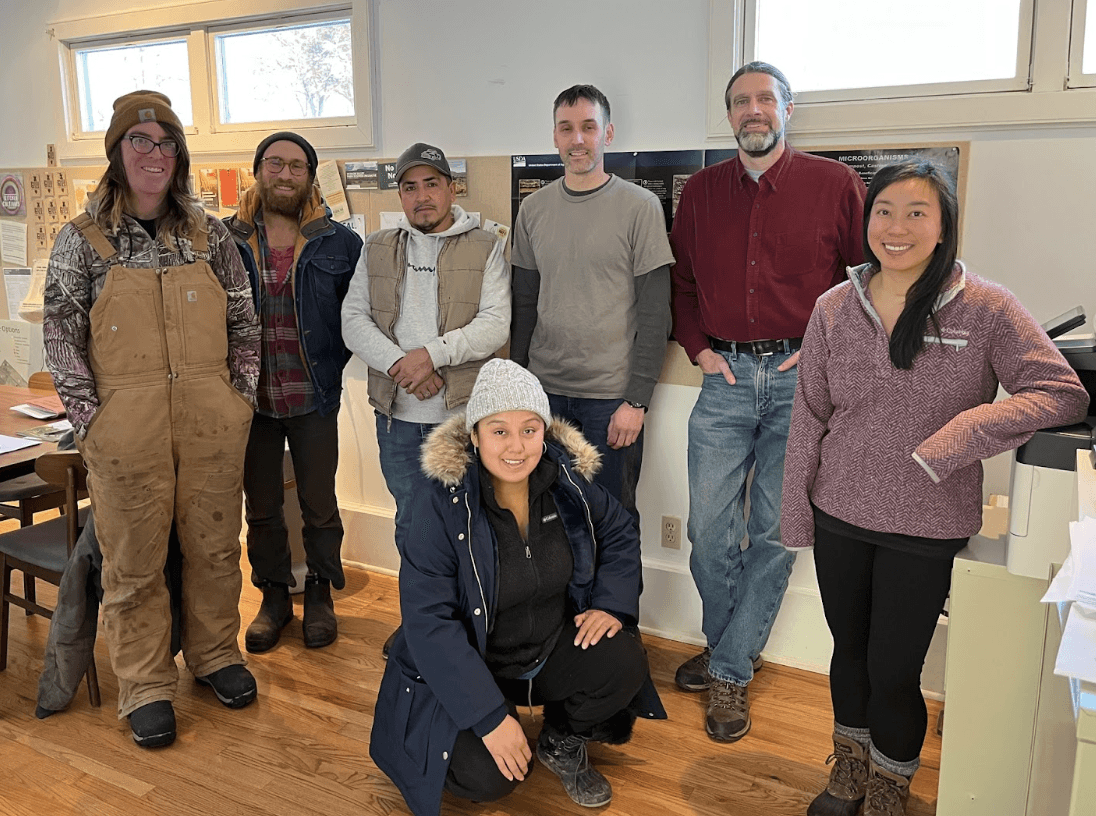

Introducing the 2024 Farm Business Incubator Cohort!

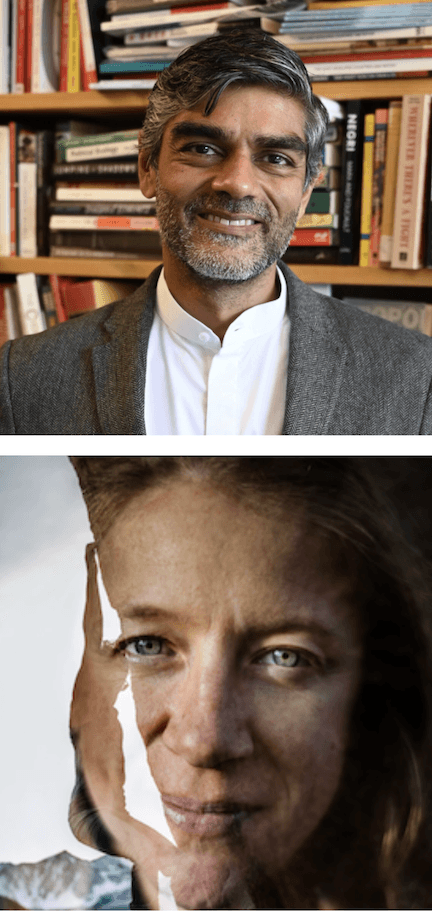

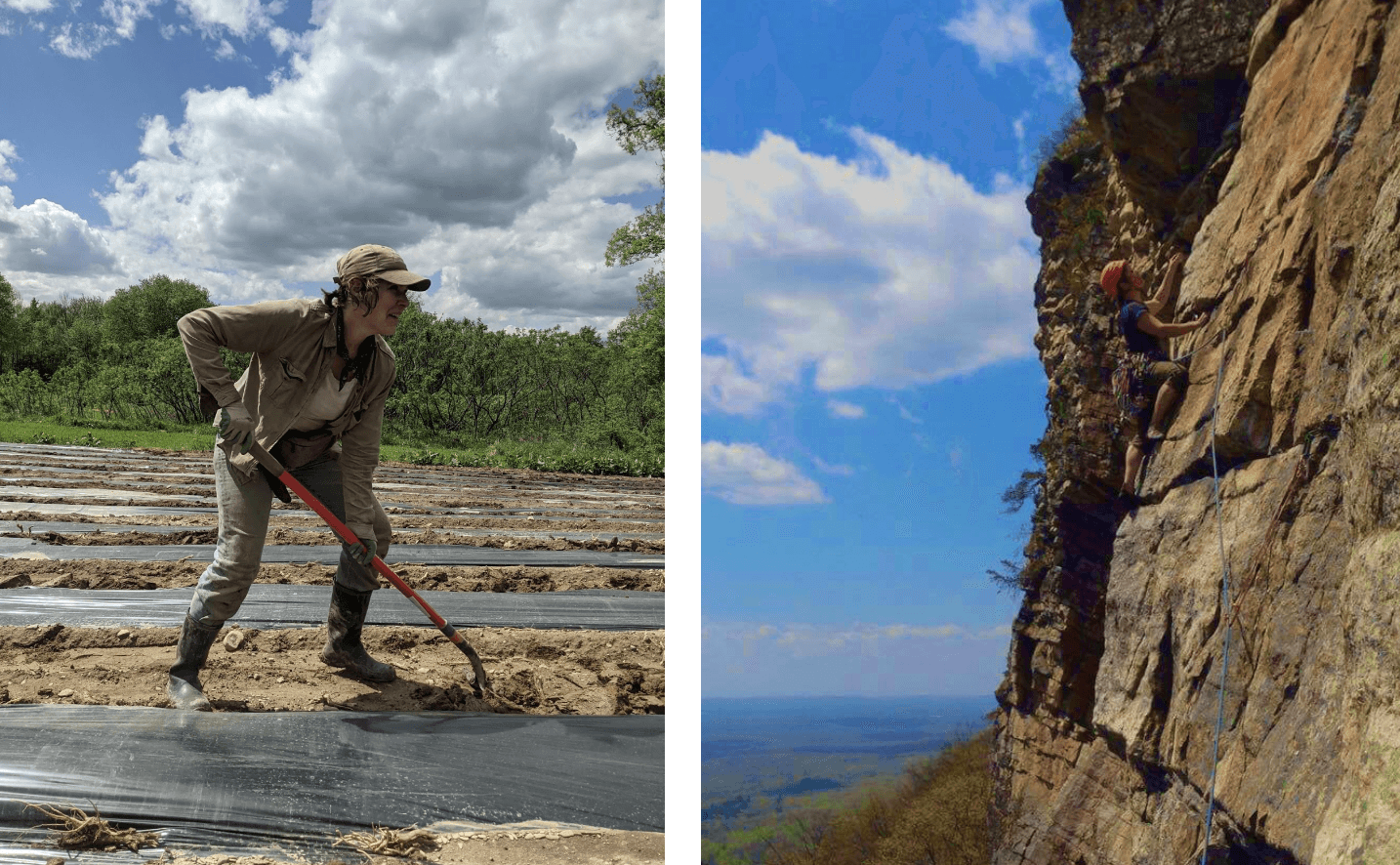

Welcome to our two new Glynwood Ambassadors, Raj Patel and Kate Rutherford!

This fall, Glynwood welcomed two new members to round out our Development and Communications Team. Jenn Hayden came on board in September as Director of Development, and Megan McGuinness joined the team in October as Development and Communications Coordinator.

Growing high quality crops and livestock no matter the weather has been a goal of farmers since the earliest days of agriculture. Although farming traditions in the Hudson Valley offer valuable risk management strategies specific to the region and developed over centuries, the growing disruptions caused by climate change go far beyond the challenges faced by previous generations of farmers. This means that today’s farmers need new management tools—tools that past generations did not need—to be successful.

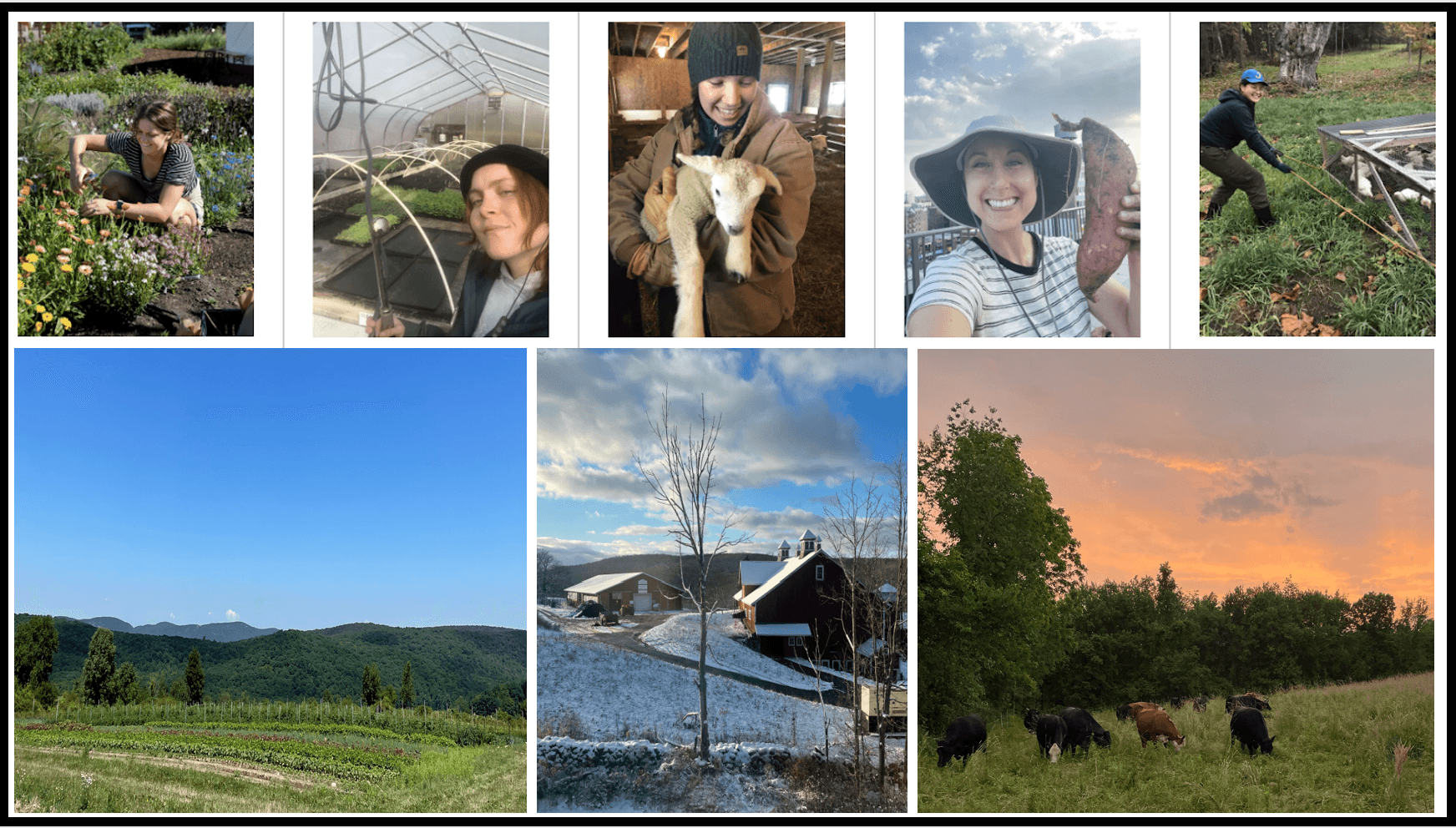

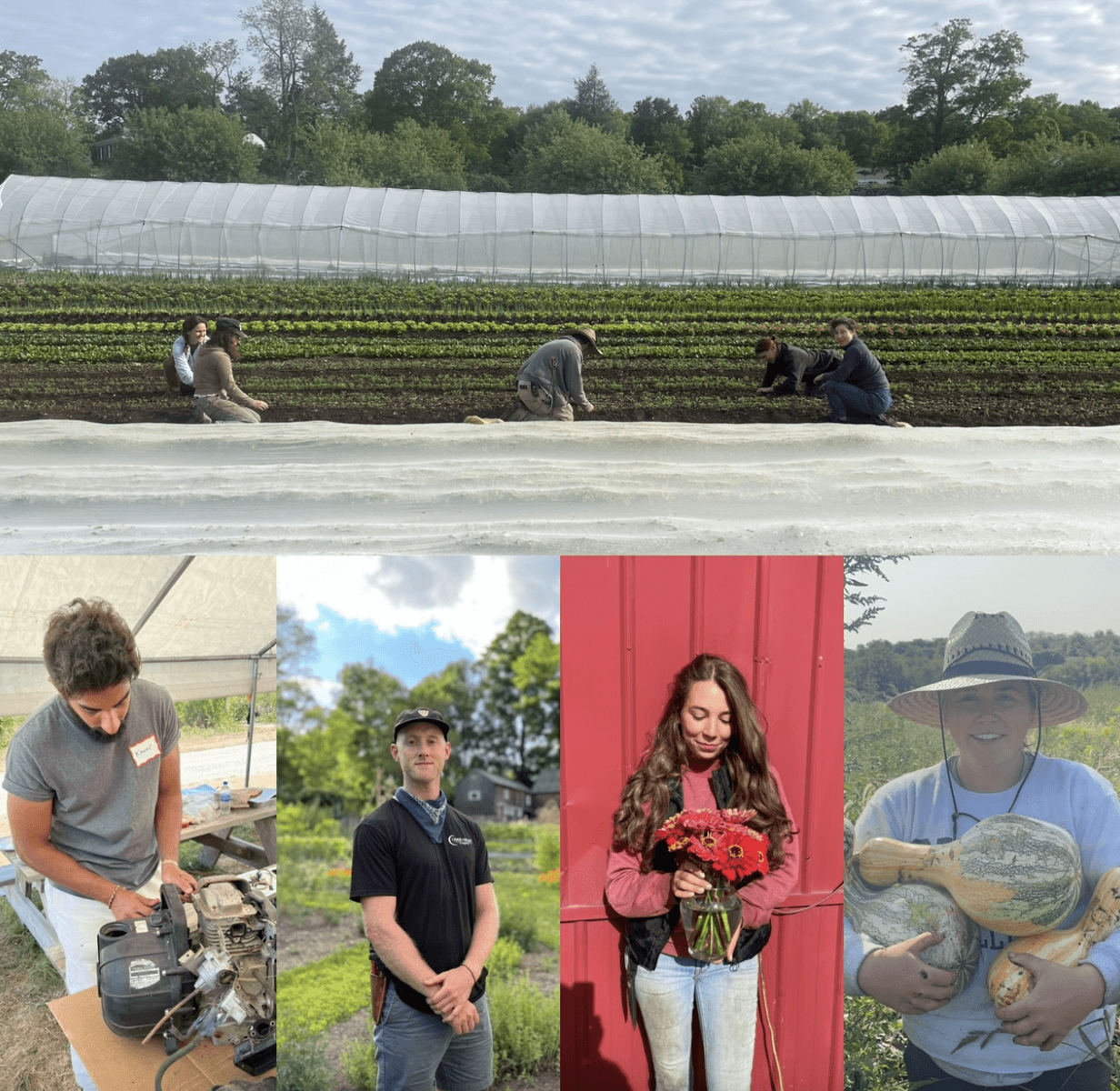

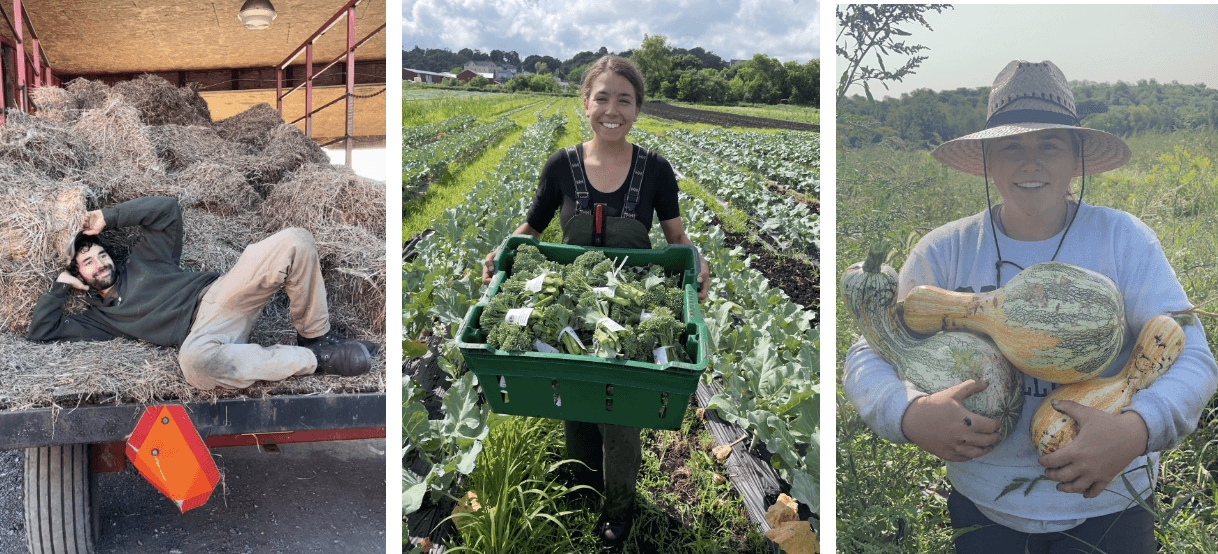

The Hudson Valley Apprenticeship, launched by Glynwood in 2022, is a decentralized apprenticeship program that provides education, training and mentoring to a cohort of aspiring farmers across the Mid-Hudson Valley. Through a dynamic set of hands-on and classroom-based learning opportunities, exercises in goal setting and mentorship from some of the region’s most experienced farmers, apprentices learn the foundational agricultural skills needed for success in their future careers as farmers and food system professionals.

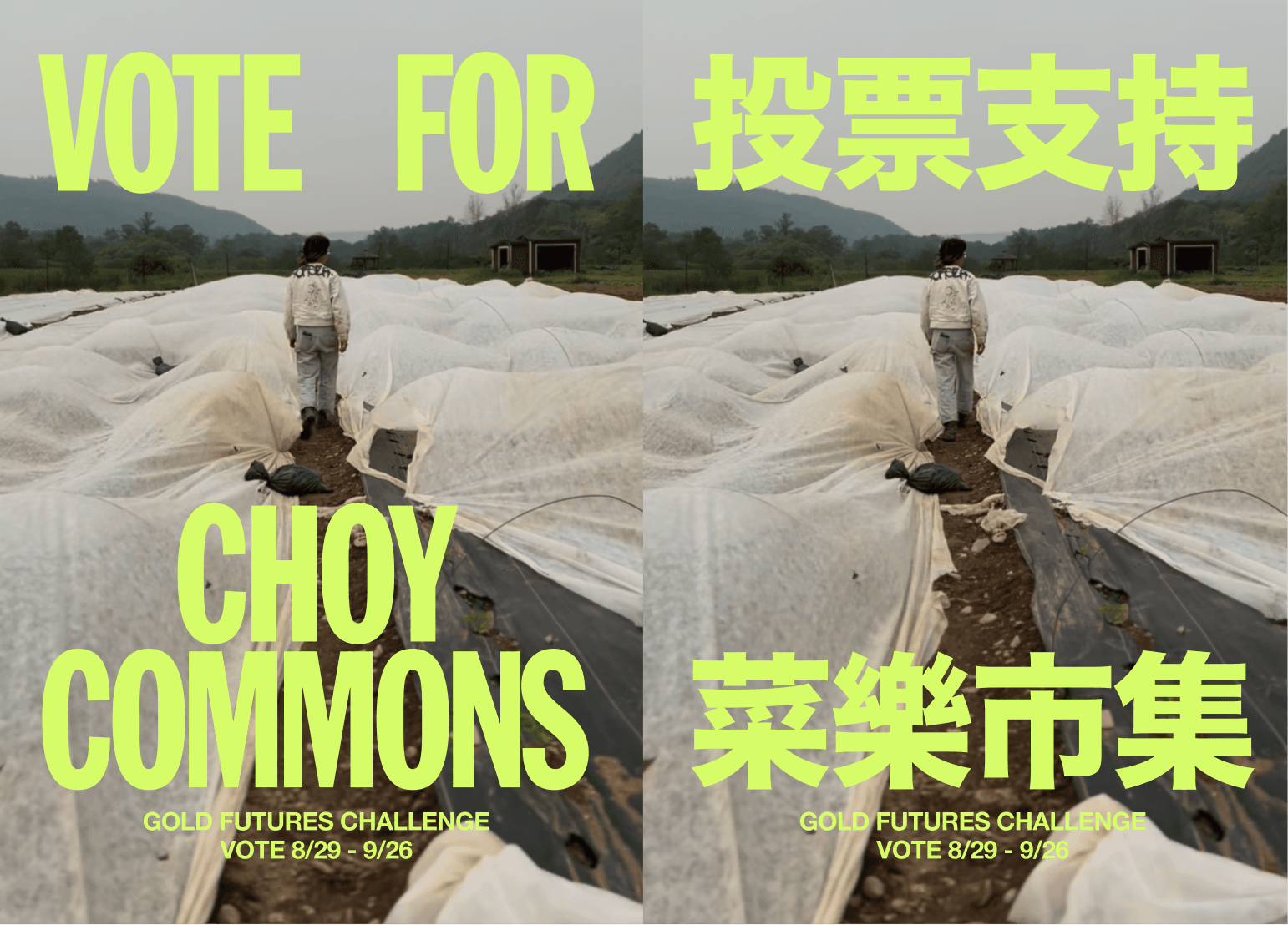

Choy Commons was created in 2021 by Asian American farmers and organizers in New York City and the Hudson Valley who came together to weave relationships between Asian and Asian American & Pacific Islander (AAPI) growers, mutual aid groups, and community-based organizations. Their goal? To preserve ancestral foodways and provide culturally important produce to those in need.

Ready to roll up your sleeves? Join us for a community-powered ecological restoration project!

We need your help restoring about 3 acres of farmland by removing undesirable plants and replanting with desirable native plants that produce food for people, forage for our livestock, and high quality habitat for beneficial wildlife like native pollinators and birds.

Hi friends! My name is Maddie and I use she/her pronouns. I hail from the bluegrass fields of Kentucky and have also studied architecture at Washington University in St. Louis and designed affordable homes in Seattle and Sacramento. I am currently pursuing my Master of Architecture at the Harvard University Graduate School of Design.

If there’s ever been a question about whether farmers markets play an important role in building just, healthy regional food systems, the newly-formed World Farmers Market Coalition (WFMC), which just held its inaugural assembly in Italy a couple of weeks ago, represents an emphatic and inspiring affirmative answer. The assembly, the first of its kind, attracted market managers and organizers from across the globe to come together to ensure markets continue to strengthen as we strive toward more resilient food systems.

We are excited to introduce our 2023 Apprentices, who have traveled here from near (Putnam County) and far (Colombia). This colorful bunch is already leaning into this next learning adventure, and already teaching us so much. We look forward to guiding each other and growing together over the next 7+ months of the apprenticeship.

The National Audubon Society will honor Glynwood Center for Regional Food and Farming (Glynwood) President, Kathleen Finlay, with the Rachel Carson Award at the organization’s 20th Women in Conservation Luncheon at Bryant Park Grill in New York City on Thursday, May 4, 2023. Inspired by Carson, whose ground-breaking 1962 book “Silent Spring” helped launch the modern environmental movement, the award recognizes visionary women who demonstrate great leadership and commitment to conservation, both locally and globally.

When a pandemic response policy expired at the end of February before the planned official end of the public health emergency, tens of millions of low-income people across the country lost a significant chunk of their monthly Supplemental Nutrition Assistance Program (SNAP) benefits, catching many by surprise. This emergency legislation had allowed every SNAP household to receive the maximum monthly food stamp benefit, regardless of their income. Now, with these emergency allotments coming to an abrupt end, SNAP participants have lost at least $95 in monthly benefits–what could be a week's worth of groceries–and many households have seen much larger cuts of hundreds of dollars a month.

Glynwood’s Food Sovereignty Fund (FSF) is a transformational community-based food justice and health equity program designed to address various inequities in our food system. Through it, we help farmers connect with hunger relief projects to provide delicious, nutritious, and culturally appropriate food grown by regional farmers to these organizations and their clients. It is a stand-out example of our commitment to supporting community control of the food system–a defining principle of food sovereignty.

In recent years, Community Supported Agriculture (CSA) has emerged as a broadly transformative model that increases the economic viability of small and mid-sized farms, strengthens relationships between producers and consumers, boosts local economies, and delivers overwhelmingly positive impacts to people’s lives. CSA members experience a full growing season with the farm, drawing them closer to the cyclical nature of farming and allowing them to share in the farm's abundance.

But while CSA works beautifully for small-scale vegetable farms and many consumers, its high up-front cost is prohibitive for people facing financial stress or uncertainty. With a growing collective desire to incorporate food justice into their farm operations, farmers across the country have developed many strategies to increase economic access to CSA while maintaining profitability.

In early February, Megan Larmer, Glynwood’s Senior Director of Regional Food Programs, and Kate Anstreicher, Glynwood’s Program Manager, braved Chicago’s notoriously brutal winter to attend CiderCon, an annual conference organized by the American Cider Association. Attracting everyone from apple growers to cider enthusiasts to beer aficionados looking to branch out, CiderCon is an inspiring, multifaceted event where attendees from around the world can admire state-of-the-art canning equipment, get in a spirited argument about single-varietal ciders versus blends, and swirl a glass of experimental perry while discussing the unparalleled majesty of an old pear tree.

Glynwood now has two new electric vehicle charging stations in the office parking lot, which will allow us to charge four cars at a time. Installing these EV charging stations was a larger task than expected, including trenching hundreds of feet to run a new transformer, jackhammering through bedrock, and "discovering" things underground.

We’ve also built capacity for at least two additional stations, to be installed when demand grows. Concurrent with this project, we purchased a new electric car for Glynwood, and the difference in charge times from a standard outlet (several days) to these dedicated units (just hours) is striking.

Founded in 2007, Glynwood’s apprentice program began when the organization launched the expansion of the Community Supported Agriculture (CSA) initiative. Over the years, Glynwood has trained dozens of farmers, providing them with a solid foundation in regenerative agriculture as well as education in managerial skills.

Meet Bill Ladd-Cawthorne, a 2013 Glynwood Farm Apprentice, and learn about his path to Glynwood and what he’s been up to since his time on the farm.

When Friday noon rolls around, the hum and hustle of a lively afternoon at Glynwood’s Farm Store begins to find its steady rhythm, like good background music in my ears. I flick on the lights, set a tall stack of logs aflame, then go out and pull the bins holding today’s harvest inside. Heavy as they are, flipping open a snap-lock bin sent by the Vegetable Team can feel like unwrapping a present. Inside the first one I open, 10 heads of red cabbage glisten in their snug pile: small and large, circular and oblong, they radiate a still-alive energy. Popping open another bin, I find a vibrant spectrum of microgreens puffed up in plastic bags like those harboring goldfish at a carnival.

After this past year at Glynwood, I treasure our produce, though I know only morsels of what really goes into it. It’s clear that bringing good food to market requires time and care beyond the field, too, but I’ve long wondered what it takes to bring the harvest to organized, store-ready cleanliness. When farmers Jarret and Leah asked me to assist them at the Wash/Pack Shed during our apprenticeship’s absence, I got my chance to find out.

Regional food policy work has emerged as a promising approach to developing equitable, sustainable, and vibrant food and agriculture systems. Yet, there is a need for much more resources and information to support the work of practitioners working at this scale. So it is exciting that a new project being led by the U.S. Department of Agriculture Agricultural Marketing Service (USDA AMS), Ohio State University, the John Hopkins Center for a Livable Future, and Colorado State University is aimed at better understanding regional approaches to strengthening food systems.

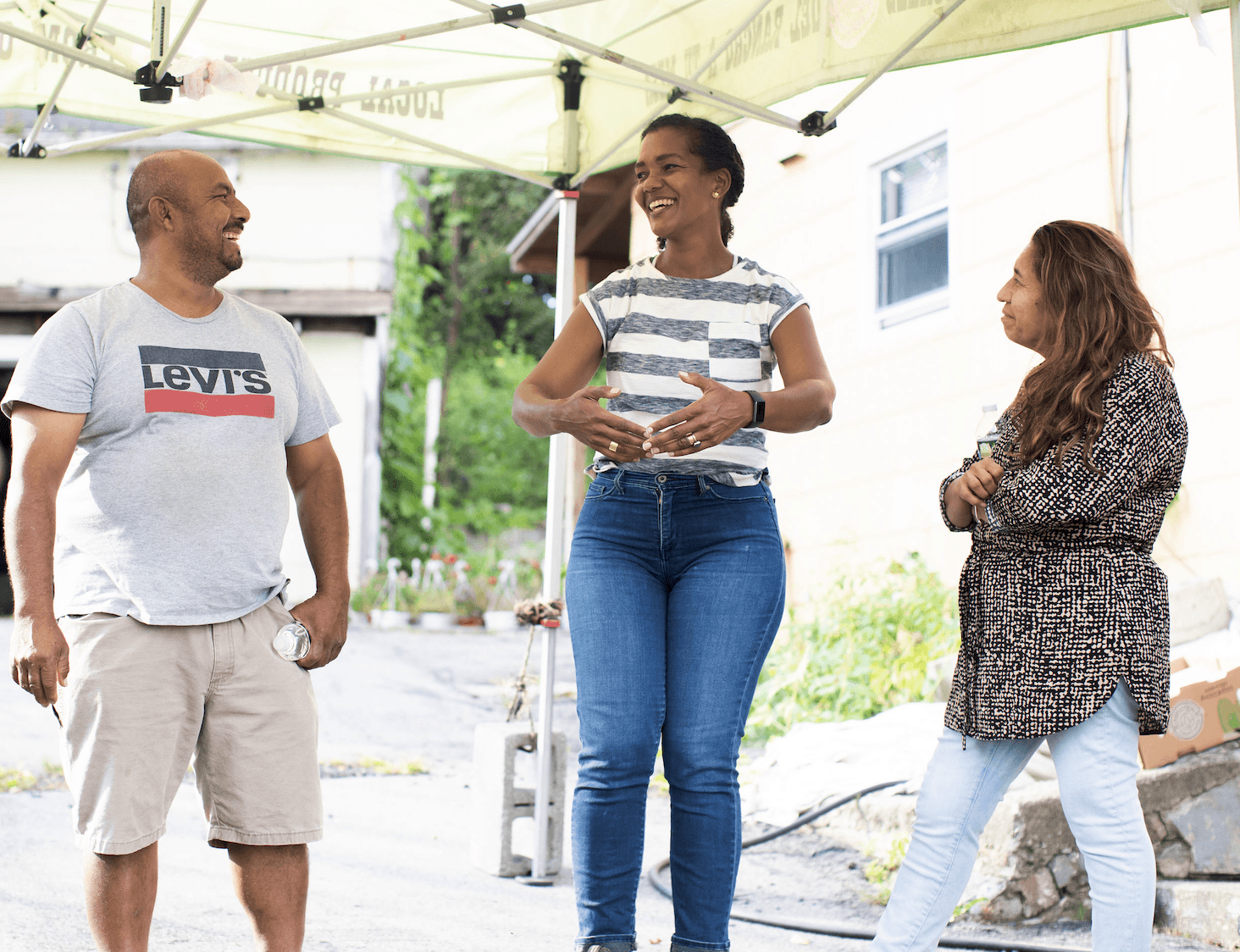

Each winter, Glynwood welcomes a new cohort of farm entrepreneurs to the Hudson Valley Farm Business Incubator (HVFBI) program. Through this program, we have provided customized technical assistance to over twenty new and growth-stage farm entrepreneurs, including farmers like Jose Roberto Rodriguez of Three Sisters Farm (pictured above).

We are pleased to announce the addition of four new farm businesses whom we will be engaging in their first year of HVFBI participation in 2023.

Deep winter is the time for rest and reflection on many farms. Here at Glynwood, the rhythms of the farm slow down as our crops and livestock shelter inside, protected from the wet, cold and windy weather that is winter in the Hudson Highlands. Our farmers spend much of the winter inside as well, where they are busy cleaning and organizing workspaces, repairing and replacing equipment, and finishing up their record-keeping in preparation for looking back over the successes and lessons learned last year and looking forward to making plans for the new growing season ahead.

As December settles in, we sadly say goodbye to our farm apprentices as they fledge the nest and continue onward in their farming journey. Now we Glynwood full-time farmers get our chance to slow our pace, reflect, and spend time planning (and interviewing for the next batch of apprentices!) for next year. But day-to-day farming never completely ceases.

As the days grow shorter and the farm’s rhythms begin to slow, our apprentices reach the end of their work with us. This year, we asked them to reflect on a favorite space at Glynwood and what it means to them. Their words invite us all to pause every now and then in our busy lives and give thanks for the power of land, people and community to make each year unique at Glynwood Farm. Farewell, Suz, Hania, Miya, H.e, and Carly. We will miss you!

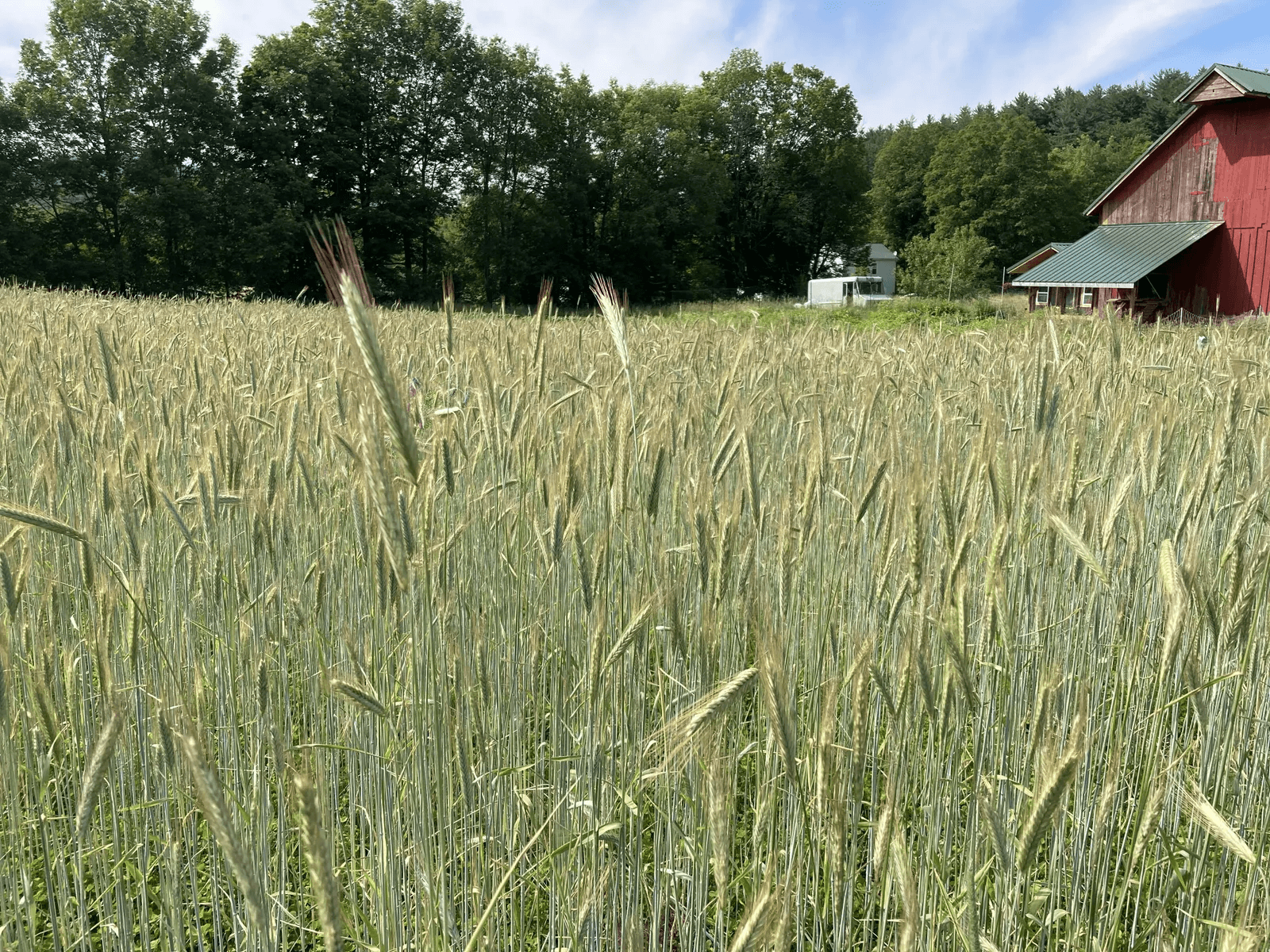

Last month, we enthusiastically launched our Grains & Staples retail program at the Glynwood Farm Store. This project centers on a call to make nutritious, regionally-grown grains more accessible to our community through a new CSA add-on and a growing retail selection in our Farm Store.

Our inaugural season is meant to introduce and familiarize Glynwood CSA members and shoppers at the store to the inspiring range of products now available in the Northeast, and in particular in the Hudson Valley. CSA shareholders will come to recognize products ranging from traditional roasted cornmeal from the Ganondagan Iroquois White Corn Project to an All-Purpose (AP) wheat flour from Milestone Mill called “Tom”, which began development just over a decade ago through a Cornell University led research project that continues to this day called the Value Added Grains for Local and Regional Food Systems project and in the Hudson Valley Farm Hub’s ongoing small grains field trials. Several of the CSA’s products will also be available in the newly designated Grains & Staples section of our Farm Store, so customers who could not commit to a full season can still sample to their hearts’ content.

We are thrilled to announce that Glynwood has been awarded a three-year U.S. Department of Agriculture (USDA) Beginning Farmer and Rancher Development Program grant to expand our Hudson Valley Apprenticeship program! The Hudson Valley Apprenticeship (HVA), an initiative launched in 2022, supports apprentices at mentor-partner farms. In this program, apprentices gain a solid foundation in the principles and practices of sustainable vegetable production through a combination of hands-on learning and in-field mentoring with select farm mentors across the region, as well as through classroom-based education facilitated by Glynwood. The USDA grant will help us grow our onsite apprenticeship program and allow the HVA to reach even more new entry farmers. All program elements will be rooted in Inclusion, Diversity, Equity, and Access (IDEA) principles, recognizing Glynwood’s role in addressing racism and inequity in our country’s food system.

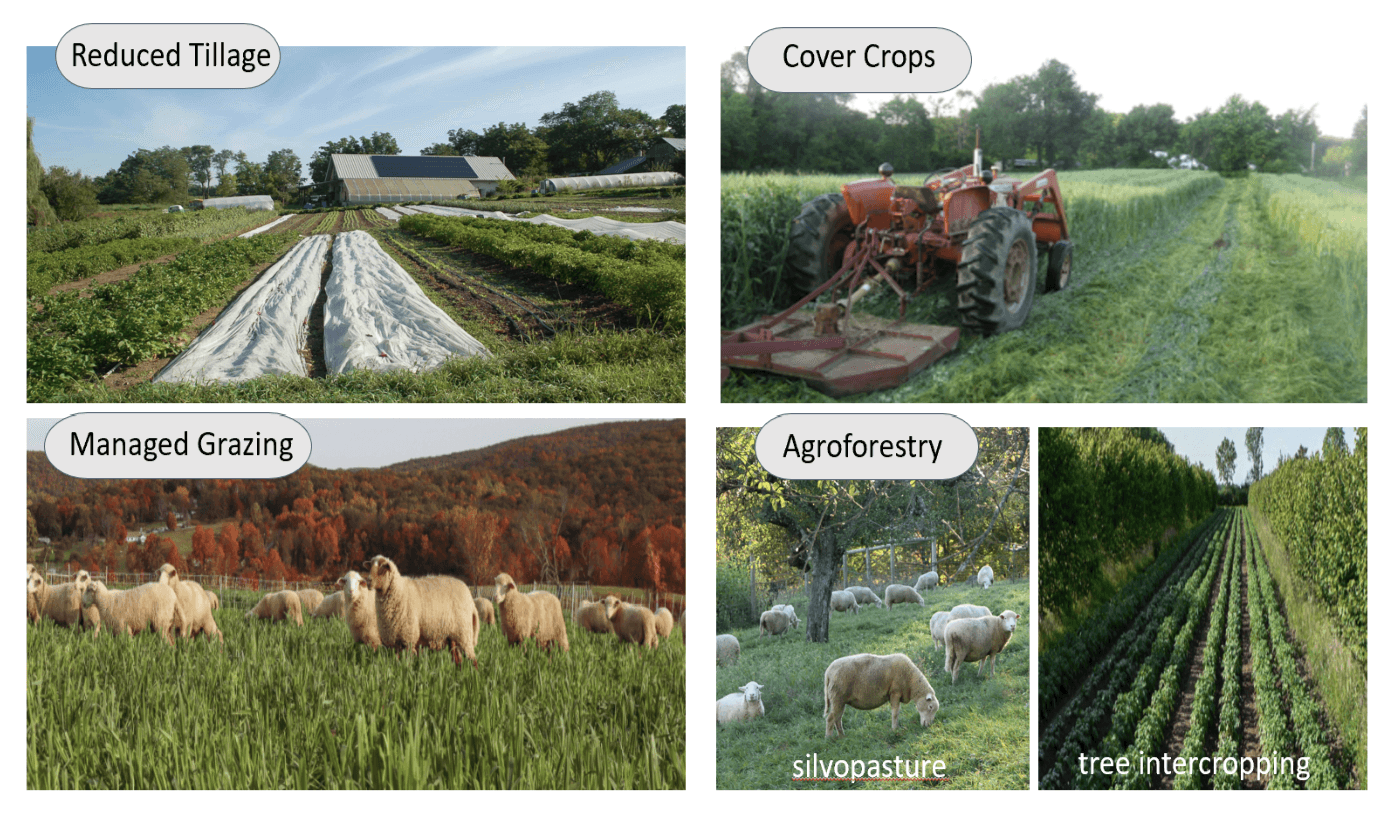

We are delighted to announce that Glynwood, along with an incredible team of national leaders in agriculture, soil science, environmental justice, and climate science, has been selected by the USDA to receive $20 million in funding from the Partnership for Climate-Smart Commodities Program. This ambitious five-year project will help farmers adopt climate-smart practices as well as measure the effects of these practices on the environment, on the farmers who have adopted them, and on regional markets.

The New York cider industry is on the cusp of becoming a world class beverage business. Cider experts will be in high demand as our place-based beverage achieves the worldwide popularity it deserves. But how do we build cider expertise and appreciation among members of the public? Well, orchards are our very own version of California vineyards and, like the wine connoisseurs of Napa Valley in the 1970s, New York cider enthusiasts are trailblazers. Working with our partners at the New York Cider Association and Angry Orchard, we set out to recruit the next generation of cider ambassadors by hosting a Cider Supper to introduce them—and, through them, their audiences—to the stunning quality and variety of New York cider.

Next month we will have to say farewell to our cohort of 2022 apprentices. They are an amazing bunch – incredibly talented, competent, compassionate humans – and we are glad to have one more month with them. But, while we are still wrapping up this current farming season, we are at the same time preparing for the next: specifically, we are currently recruiting for 2023 apprentices!

Christina Chan joined the Glynwood team in October 2022 as our Farmer Training Program Coordinator. Originally from Brooklyn, Christina has long considered food and eating a vital connection to her family. It wasn’t until obtaining her Masters in conservation science, though, that she became interested in agriculture as a way to not only build connections to people and place but also to protect the earth.

One of the most accessible farmer training opportunities in the Hudson Valley is Mid Hudson CRAFT (Collaborative Regional Alliance for Farmer Training), a free farm tour series organized by Glynwood and other regional partners every season. Hosted by regional farms on Thursday evenings, CRAFT tours involve farm walks, talks or demonstrations on a specific topic chosen by the farm host. These farm visits offer exposure to a number of diverse agricultural enterprises, as well as opportunities to develop practical skills and to network with other farmers and apprentices.

As we come towards the end of this year’s CRAFT season, we would like to celebrate the many farmers who have hosted tours and shared space and skills with hundreds of CRAFT participants, and to share some highlights from the season’s lineup.

It’s amazing what can happen when you get the right people in a room together–you can spark innovation, redirect resources to where they are needed most, or simply reinspire and fortify each other for the struggle ahead. A little bit of this magic happened when we gathered a group of Glynwood’s Food Sovereignty Fund (FSF) partners–farmers, Accountability Council members, and frontline food access workers–on a rainy early-October Wednesday to visit four food access organizations in Brooklyn and the Bronx.

We started the day at St. Ann’s Episcopal Church in the South Bronx, where Rev. Matthew Engleby, Brian Lyons, and a team of long-time volunteers were preparing to distribute food to the hundreds of clients already waiting outside in the early morning drizzle. The distribution would include fresh produce sourced from FSF partner Star Route Farm. Brian remarked that the quality and freshness of Star Route’s produce has simplified their distribution logistics: with cooler space at a premium, the produce can be left out overnight and still be fresh and crisp when handed out the next day.

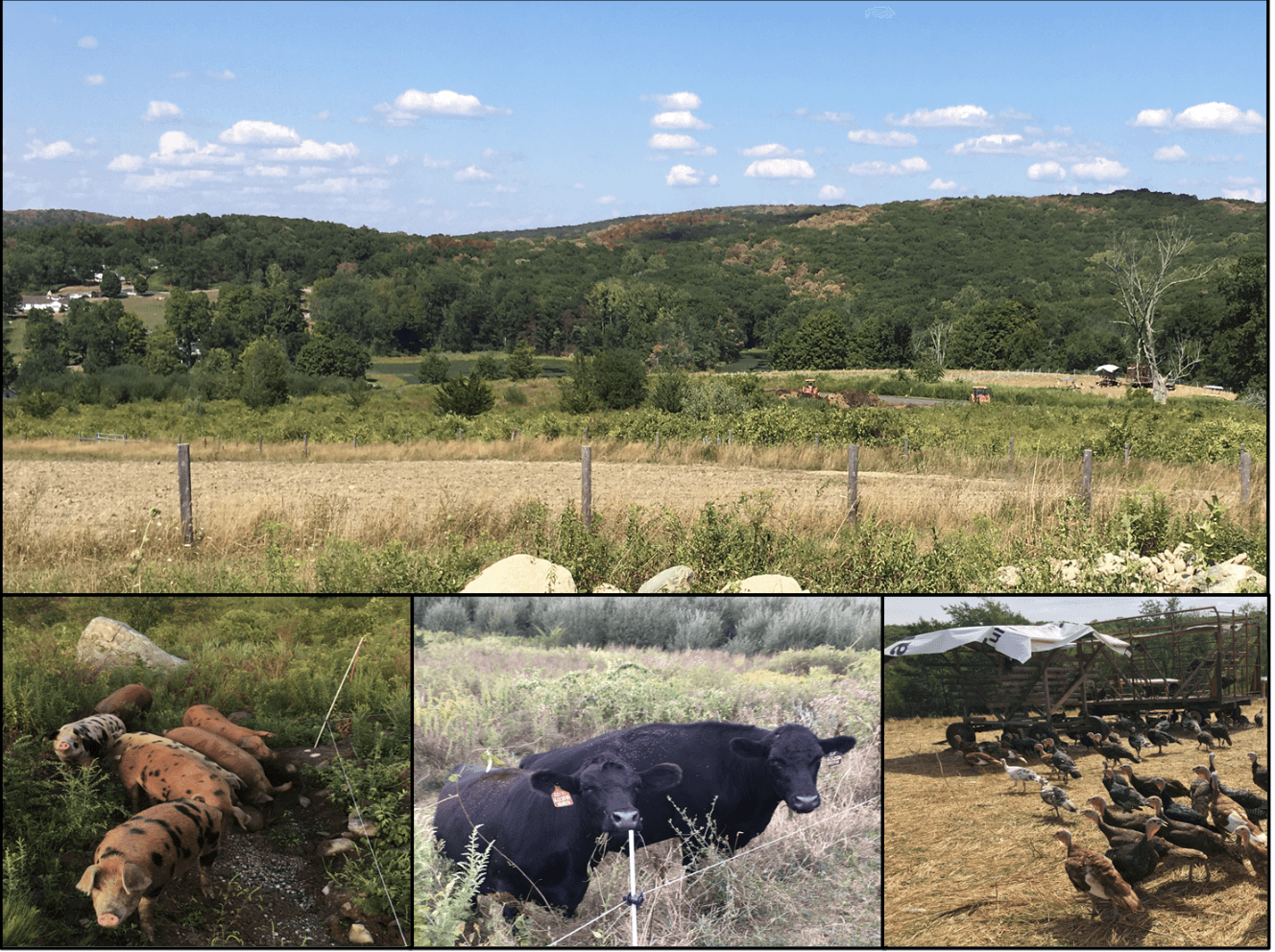

Over the past six months, our Livestock Team has been skillfully raising their biggest flock of heritage-breed turkeys yet! When you drive into Glynwood, you might notice these boisterous birds, proudly gobbling and foraging in the pasture.This year, we are raising a diverse mix of five heritage-breed species, including Standard Bronze, Bourbon Red, Chocolate, Black Spanish, Blue Slate and Midget White.

With the recent addition of a Grains and Staples project to Glynwood’s Regional Food Programs, we are excited to support a new foundation for an emerging sector of the Northeast food system. Our Grains and Staples Program seeks to build markets for emerging crops and promote their production in systems of regenerative agriculture. At Glynwood, we see exciting potential for cultivating a dynamic local grains outlet at our very own Winter Farm Store, in close collaboration with the farmers and producers who are making this movement possible. To that end, we will be launching a pilot Grains & Staples CSA share add-on that will run alongside our annual Winter Vegetable CSA.

The Hudson Valley Apprenticeship program provides education and support to ten apprentices across the Hudson Valley. Previous posts have introduced apprentices Sophia at Four Corners Community Farm, Melissa and Janine at Phillies Bridge Farm Project, Eric at Stonewood Farm, and Betty and Kanav at Ecological Citizen’s Project.

In our final spotlight on participating HVA farm apprentices, we have the incredible team at Dig Acres in Chester, NY.

Steffen Hyder joined the Glynwood team in late September as Associate Director of Buildings, Infrastructure and Grounds. Born and raised in Massachusetts, Steffen is a decades-long resident of the Hudson Valley. Having originally come to study art and history at Bard College, he fell in love with the region for its distinct terroir and ecological character. Steffen has worked as an archaeologist, shepherd, historic preservationist, stonemason and woodworker, and has a deep background in the building trades.

We are thrilled to share that Zoraida Lopez-Diago is joining Glynwood as Vice President of Development, Communication, and Strategic Partnerships on November 1st. She will be part of the organization's core leadership and responsible for several development, communications, and strategic functions at Glynwood to support its mission and programs.

The Hudson Valley Apprenticeship program provides education and support to ten apprentices across the Hudson Valley. Over the last few months, we’ve written about HVA apprentices Melissa and Janine at Phillies Bridge Farm Project, Eric at Stonewood Farm, and Betty and Kanav at Ecological Citizen’s Project. Today, we’d like to introduce Sophia Perkins.

Are you interested in helping to harvest leftover produce from our fields for donation? If so, consider joining our Glean Team! Gleaning, as defined by the USDA, is the practice of “collecting excess fresh foods from farms, gardens, farmers markets, grocers, restaurants, state/county fairs, or any other sources in order to provide it to those in need.”

Last month, Glynwood’s Cider Project organized its second annual sensory tasting event to analyze the products of cider fermentation trials. Featuring fruit from trees donated and planted by the Cider Project in 2017, these trials are an ongoing effort to identify unique cider flavors, structures, and even terroir by fermenting juice from distinct orchards and apple varieties (separately, but under uniform conditions), then comparing and contrasting the ciders in a controlled tasting environment.

Oh, what a difference a few months can make! Back in June, as a beautiful, lush spring shifted slowly into deep greens of early summer, I wrote about the challenges of too much water at Glynwood Farm. Just three months later, we are suffering from the effects of a flash drought and unprecedented heatwaves: our livestock farmers have been feeding hay for the last six weeks because our pastures have stopped growing; our lake and pond levels have dropped by six inches or more; and one of our wells has gone dry.

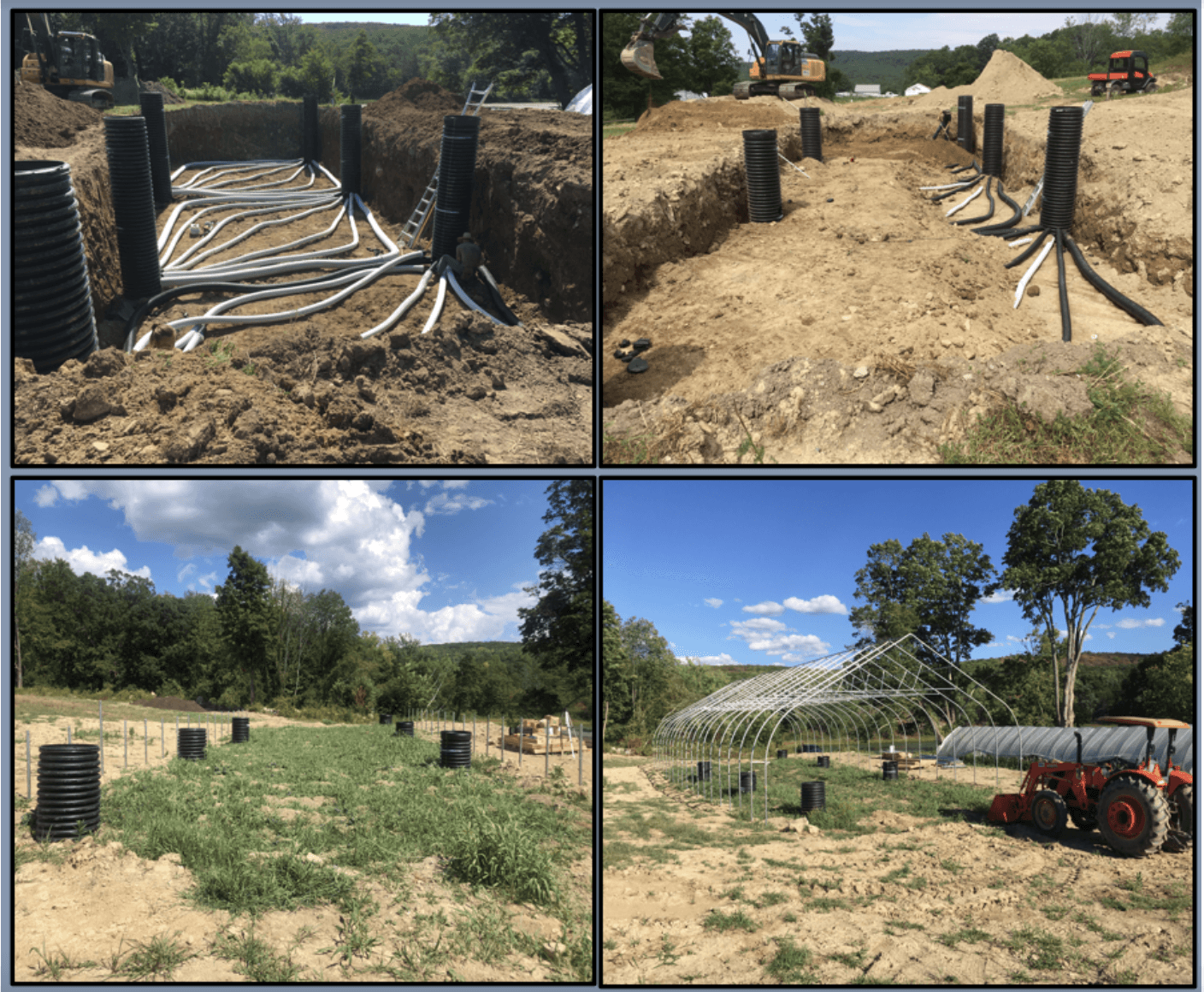

Farming during the climate crisis requires constant re-evaluation of our land management practices and production systems. At Glynwood, we have greenhouses where we grow food through the winter and start early crops in the spring. While some greenhouses are unheated, one is heated with propane to provide extra warmth to the crops. This summer, we installed a ‘climate battery greenhouse’ at Glynwood—a simple yet innovative system that creates a versatile indoor growing space that can be used year-round without relying on fossil fuel for added climate control.

This month, we want to introduce you to Melissa Schultheis and Janine Connell, who are apprenticing at Phillies Bridge Farm Project as part of the Hudson Valley Apprenticeship program.

The Hudson Valley Apprenticeship (HVA) is a decentralized apprenticeship designed to prepare farm apprentices across the region to successfully manage their own climate-resilient farm enterprises. (For a full description of HVA, read the blog post here.) In its pilot year, the HVA is supporting and resourcing apprentices at six Hudson Valley farms including Phillies Bridge Farm Project as well as DIG Acres, Four Corners Farm, Stonewood Farm, Maple View Farm, and the Ecological Citizen’s Project at Longhaul Farm.

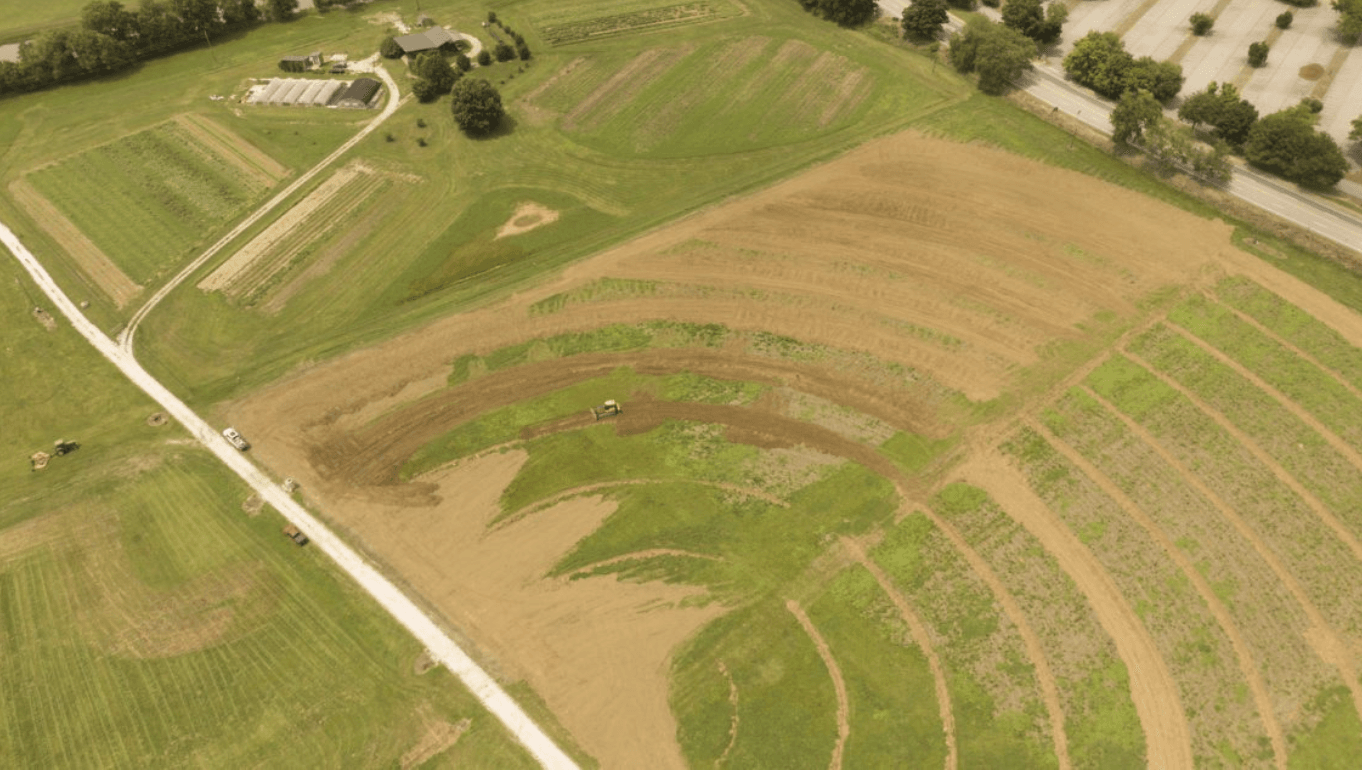

Back in 2018, Laura Lengnick, Glynwood’s Director of Agriculture, was invited to lead a community-based design process to reimagine the 80-acre farm on the main campus of Clemson University in South Carolina. Just last month, she was on site to see the first phase of the new design get underway: the installation of earthworks to improve drainage on one of three new climate-resilient farming systems planned for the site.

In early August, Glynwood hosted 30 livestock producers, extension agents and other industry stakeholders for an in-person livestock picnic. The gathering was an opportunity for the Hudson Valley Livestock Producers Group–founded by Glynwood in 2020–to break bread, reflect upon the season, share ideas, and discuss the preliminary findings of the USDA Regional Food Systems Partnership (RFSP) grant, which Glynwood and Cornell Cooperative Extension began working on in early 2022.